What are submersible pumps?:

Submersible pumps are a type of centrifugal pump designed to function with the pump and motor submerged in the fluid to be pumped. The motor is sealed in a way that prevents even tiny amounts of the fluid from seeping in, which would cause the motor to short out.

Since submersible pumps do not use a motor above grade, floor space is better utilized, and the overall cost of the installation may be reduced. They also tend to have lower maintenance costs and create less noise than pumps which have the motor mounted at grade. There is also no concern for priming this type of centrifugal pump, and less concern about cavitation, since the impeller and casing are always submerged and there is no suction pipe with this type.

How do they work?

The exact type of motor and pump that comprise a submersible pump depends upon the application and installation details. Generally, there are two main types, those that operate down in a bored well, and those that operate in a sump, wet well, or basin.

The type that operates in a bored well normally includes a very skinny submersible motor located at the bottom of the pump. Just above the motor is an inlet screen and suction bell, which directs the fluid into the centrifugal pump stages that consist of impellers and diffuser bowls. Usually these pumps are multi-stage, i.e., have more than one impeller and diffuser, so they can be used to pump fluids from very deep wells.

Flows for both types range from less than 10 gallons per minute for a residential version, to several thousand gallons per minute for irrigation, industrial, or municipal applications.

Submersible pumps normally handle clean or dirty water or sewage, so iron construction is most common. Home well pumps and lighter duty sump or utility pumps are often found in plastic construction. And, some manufacturers make this pump type in more exotic alloys for corrosive and abrasive applications.

Some wastewater submersible pumps include graining teeth on the impeller to grind or chop the waste. Often these pumps include a level control as part of the equipment. Some are sold in duplex arrangements that offer an alternator that switches which motor starts when high levels are reached in the sump. This keeps the motors from having to start too often, which could cause a motor starter to fail.

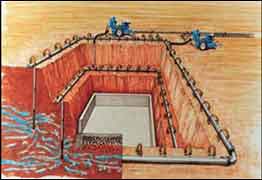

Where are they used?

Submersible pumps are used in a huge variety of applications. The type that operates in a well is used for drinking water supply, irrigation, dewatering, and oil production. The type that operate in sumps, pits, wet wells, or basins is normally used to pump wastewater, which might be from groundwater that seeps into homes and other buildings, floor and equipment drains in a building, This type is also used in other applications, including pond pumps and industrial pumps in plants. They’re also integral to most municipal wastewater collection and treatment systems.